From Blueprint to Reality: A Comprehensive Guide to Steel Building Kits

Steel building kits transformed the construction industry, offering a versatile, cost-effective solution for various structures. From warehouses and workshops to residential homes and commercial buildings, these kits have transformed the way construction projects are approached. This listicle will delve into turning a blueprint into reality using a steel building kit.

Understanding the Basics

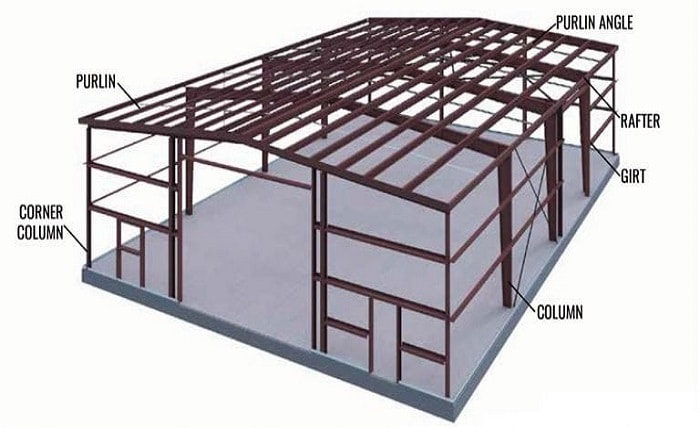

Before proceeding, it’s essential to understand steel building kits. These kits consist of pre-engineered components designed to fit together seamlessly, simplifying the construction process. Typically, a steel building kit includes primary and secondary framing components, wall and roof panels, doors, windows, and other accessories necessary for assembly.

Design and Customization

One key advantage of these kits is the ability to customize the design according to specific requirements. Whether you need a small storage shed or a large industrial facility, these kits can be tailored to meet your needs. Design options include various dimensions, roof styles, colors, and additional features such as insulation and ventilation.

Site Preparation

Proper site preparation is crucial before the construction process begins. This includes removing the area of debris, leveling the ground, and ensuring adequate drainage. Additionally, obtaining any necessary permits and approvals before proceeding with the project is essential.

Foundation Installation

The foundation serves as the base for the steel building structure, providing stability and support. The type of foundation required will depend on factors like soil conditions, building size, and local building codes. Common foundation options include concrete slabs, pier and beam foundations, and concrete piers.

Assembly Process

The assembly process can begin once the site is prepared, and the foundation is in place. These kits are intended for easy assembly, with most components labeled and pre-cut for convenience. Depending on the size and structure’s complexity, assembly can be completed quickly with the help of a skilled crew.

Erecting the Frame

The first step in the assembly process is erecting the steel frame. This involves assembling the primary and secondary framing components according to the provided instructions. Bolting or welding may secure the frame in place, ensuring structural integrity.

Installing Wall and Roof Panels

With the frame in place, the next step is to install the wall and roof panels. These panels are designed to interlock, creating a weather-tight seal that protects the interior from the elements. Depending on the design of the building, insulation may be added between the panels to improve energy efficiency.

Adding Doors and Windows

Once the walls and roof are in place, doors and windows can be installed. Steel building kits typically include pre-fabricated door and window frames, making installation straightforward. Proper sealing around openings is essential to prevent air and water infiltration.

Finishing Touches

With the main structure complete, attention can turn to finishing touches such as trim work, gutters, and downspouts. These details not only enhance the appearance of the building but also contribute to its functionality and durability.

Conclusion

The steel building kit offers a convenient and cost-effective solution for various construction projects. From design and customization to assembly and finishing touches, turning a blueprint into reality is streamlined and efficient. By following this comprehensive guide, you can ensure a successful outcome for your next steel building project.